Let's meet at Hannover Messe 2023

Hydronit at HANNOVER MESSE 2023

Come and meet Hydronit team at Hannover Messe exhibition, from April 17th to 21st.

Hydronit at HANNOVER MESSE 2023

Come and meet Hydronit team at Hannover Messe exhibition, from April 17th to 21st.

Varedo, 25th May 2021

Varedo, 30th March 2021

We are all aware of lead toxicity and its nasty effects on human health.

World Health Organization has identified lead as 1 of 10 chemicals of major public health concern as lead poisoning is responsible of several diseases. It is even believed lead to be primarily responsible for the collapse of the Roman Empire, since Romans used lead to build water piping and as wine sweetener!

But lead is a fantastic metal, when we are talking of metalworking, added to steels, aluminums and brasses.

Its self-lubricant properties and mildness reduce the amount of energy consumed and time required to machine any metal part and improves surface finishing with no significant effects on parts mechanical properties.

Government regulations around the world are progressively banning lead from most of its applications but still allow for reduced percentages of lead to be used in metals intended for metalworking.

At Hydronit we think forward and strongly follow sustainability principles. For this reason we have decided to pioneer, as first ones in Italy in hydraulics, research and testing of NO LEAD aluminum alloy extruded bars to manufacture our range of hydraulic manifolds.

First results are encouraging since we managed to obtain perfectly finished manifold blocks with a slight increase in machining times, by adopting latest generation robotized CNC machines, advanced Polycrystalline diamond tools and adapted cutting parameters and techniques.

Hydronit is phasing out lead from its aluminum blocks completely in a few weeks, as soon as the present stock of standard aluminum alloy is cleared, and passing on to its customers the advantages of working in a cleaner, safer environment.

Hydronit at BAUMA München 2022

Come and meet Hydronit team at Bauma exhibition, from October 24th to 30th.

Hydronit booth: at Federtec Hall A3, Stand 425

Varedo, 16th April 2021

Take a look at the interesting article published by our sales manager Laura Buonafede. "𝘔𝘢𝘯𝘺 𝘖𝘌𝘔𝘴 𝘢𝘴𝘬 𝘶𝘴 𝘢𝘴𝘴𝘪𝘴𝘵𝘢𝘯𝘤𝘦 𝘪𝘯 𝘴𝘦𝘭𝘦𝘤𝘵𝘪𝘯𝘨 𝘵𝘩𝘦 𝘮𝘰𝘴𝘵 𝘴𝘶𝘪𝘵𝘢𝘣𝘭𝘦 𝘩𝘺𝘥𝘳𝘢𝘶𝘭𝘪𝘤 𝘧𝘭𝘶𝘪𝘥 𝘧𝘰𝘳 𝘵𝘩𝘦 𝘴𝘱𝘦𝘤𝘪𝘧𝘪𝘤 𝘢𝘱𝘱𝘭𝘪𝘤𝘢𝘵𝘪𝘰𝘯 𝘰𝘳 𝘸𝘩𝘦𝘯 𝘵𝘩𝘦𝘺 𝘩𝘢𝘷𝘦 𝘤𝘰𝘯𝘵𝘢𝘮𝘪𝘯𝘢𝘵𝘪𝘰𝘯 𝘱𝘳𝘰𝘣𝘭𝘦𝘮𝘴. 𝘍𝘰𝘭𝘭𝘰𝘸 𝘶𝘴, 𝘸𝘦 𝘸𝘪𝘭𝘭 𝘩𝘢𝘷𝘦 𝘴𝘰𝘮𝘦 𝘯𝘦𝘸𝘴 𝘵𝘰 𝘴𝘩𝘢𝘳𝘦 𝘸𝘪𝘵𝘩 𝘺𝘰𝘶 𝘴𝘰𝘰𝘯!"

Varedo, 9th April 2021

Our CEO just publishes an article with some reflections and ideas on how to survive the challenges of 2021:

Varedo, 18th June 2021

Varedo, 6th April 2021

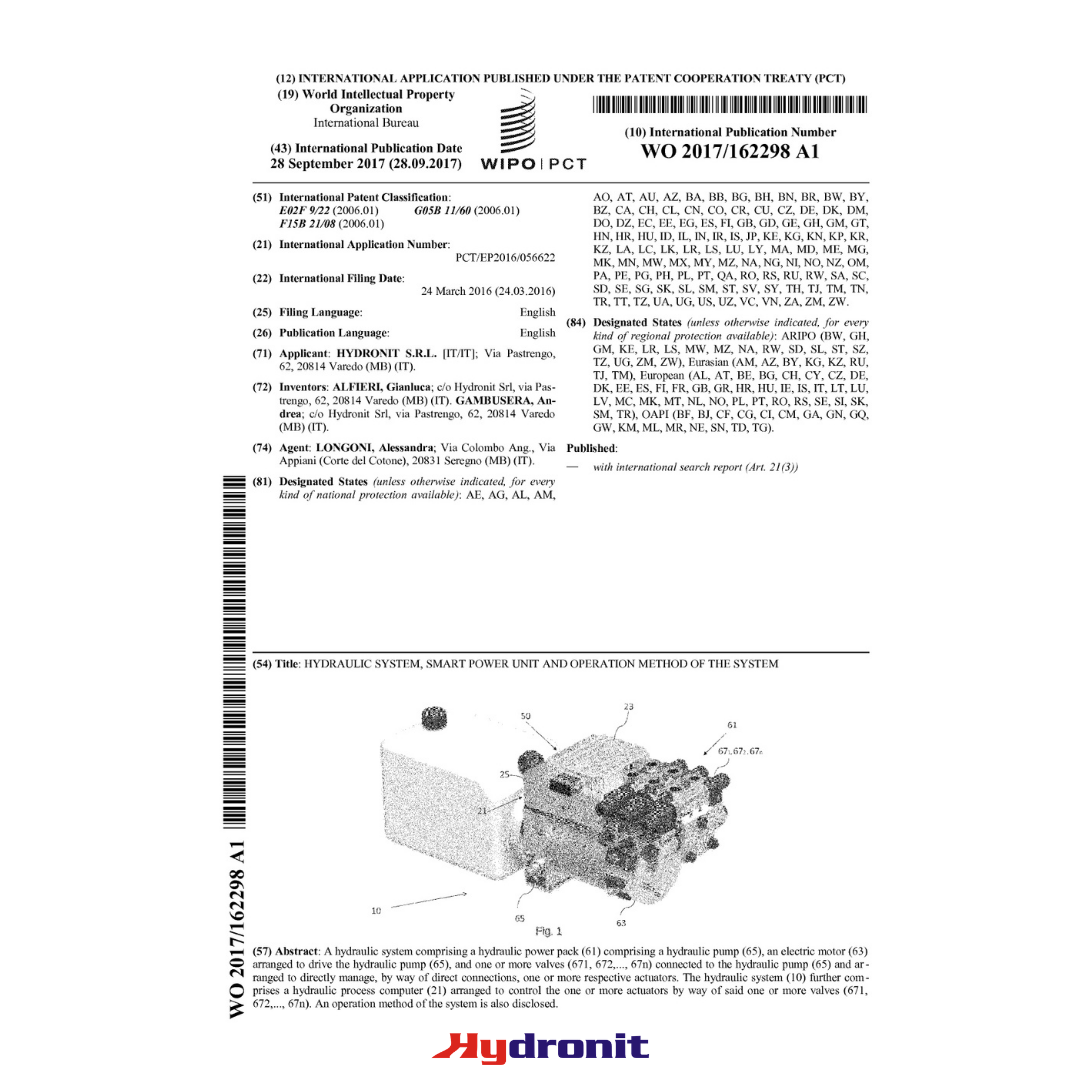

Hydronit invented the first Hydraulic Compact Smart Power Unit. But… what makes it Smart?

The Smart Power Unit is a Mechatronic Module which integrates Sensors, Electronics and Hydraulics in a single device that is:

The Smart Power Unit is patented n° WO 2017/162298 A1.

Want to know more? See www.hydronit.com and www.xdraulics.com

Article published in "In Motion" magazine, September 2019.

MATROL BI: biodegradable and renewable hydraulic fluids.